Air Permeability Analyzer

- Products

- Petroleum & Oil Testing

- Tablet Drug Tester

- Refrigeration & Cryogenic

- Life Sciences

- Laboratory

- Spectrometer

- Spray Dryer

- Rotary Evaporator

- Reactor

- Sterilizing & Cleaning

- Water Quality Analyzer

- Chemical Analysis

- Physical Testing

- Centrifuge

- Pathology Equipment

- Optical

- Ultrasonic Homogenizer

- Packaging Testers

- Compression Testing Machine

- Water Vapor Permeability Tester / Moisture Permeability Tester

- Air Permeability Analyzer

- Tearing Tester

- Heat Sealer

- Seal Tester

- Oxygen Permeability Tester

- Friction Tester

- Falling Dart Impact Tester

- Horizontal Impact Tester

- Pattern Thickness Tester

- Evaporated Residues Tester

- Inverted Pressure Sterilized Boiler

- Electronic Tensile Tester

- Heat Shrink Tester

- Leakage Tester

- Hot Tack Tester

- Disc Peeling Tester

- Roller Pressing Machine

- Sample Cutter

- Spectrodensitometer

- Hot Sticky Pull Tester

- NDT

- Agriculture & Food

- Hazardous Chemical Detection

- Fusion Machine

- Testing Chamber

- Filter Integrity Tester

- Industry Testing Device

- Featured

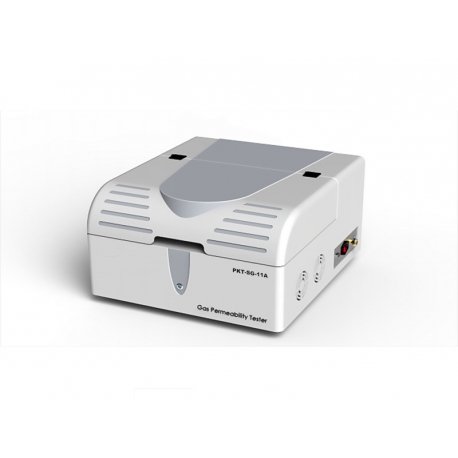

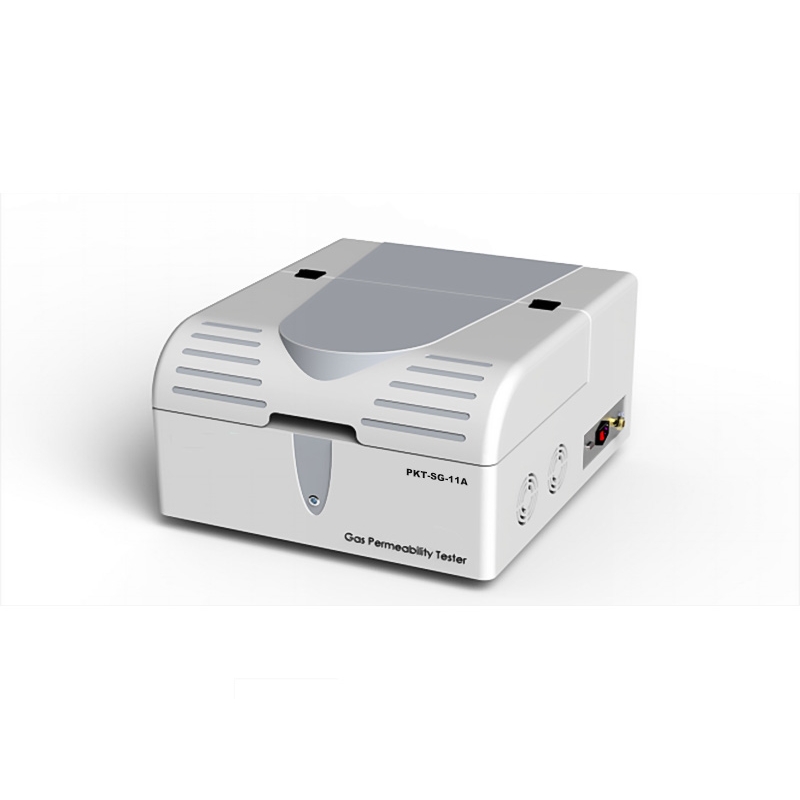

Air Permeability Analyzer

PKT-BSG series

It is applied to various gas permeation rate detection, such as O2,CO2,N2 and air, etc, in plastic film, composite membrane, High-barrier materials, sheet, metal foil, rubber, etc.

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

More info

Product function:

It is applied to various gas permeation rate detection, such as O2,CO2,N2 and air, etc, in plastic film, composite membrane, High-barrier materials, sheet, metal foil, rubber, etc.

Operating principle:

Using the principle design of differential pressure method, put treated sample in the middle of upper and bottom chamber in advance. Pressure tightly and seal, pick up the suction to the whole system, after reaching the required vacuum degree, close bottom chamber, fill with certain test gas to high pressure chamber, and adjust upper chamber pressure, keep on two sides of the sample forming constant air pressure gradient difference, the gas is under the action of differential pressure gradient, permeating from high-pressure side (upper chamber) to vacuum side (bottom chamber). Accurately measure vacuum chamber( bottom chamber) intensity of pressure variation, calculate various barrier property parameters of test sample. Fully conform to the standard GB1038,ASTM D1434.

Application characteristic

- High speed vacuum ability, reduce the vacuum time, degassing more thoroughly, high test precision.

- Short test time, high efficiency;

- Could extend to test bottle, bag;

- Power failure protection;

- A whole-process monitor, automatic recording, can reappear in the whole test process again.

- Strong graph curve function, convenient for comparison test and analysis;

- Automatic testing: Set the test parameters, test automatically proceed after starting, automatically judge the test is over and save the test result.

- There is general data base system in host software, data could be exported, could store the data, inquire, print, etc.

- Through the analysis of historical data, easy to grasp the history dynamic of the products.

Product feature

Pure semiconductor cold and hot two-way temperature control, automatically control temperature and cooling, Temperature range is more wide and more accurate, parallel work, higher reliability.

Apply base line technology, remove the system error, test result is more accurate.

Be of accurate pressure control ability, maintaining constant pressure difference.

Adopt imported high precision vacuum transducer and pressure sensor.

Embedded system control, using high quality components, ensure stability and reliability of instrument running

Meeting Standards

Compatible with the standard of various tests ISO, GB, etc: ASTM D1434、ISO 2556、ISO 15105-1、JIS K7126-A、YBB 00082003

Technical Index

Technical Specifications | Technical Parameter | ||||

PKT-BSG-11A | PKT-BSG-31J | PKT-BSG-33D | |||

Measuring range (film) (Cc / m2 • day • 0.1MPa) | 0. 1-50,000 | 0.02-50,000 | 0.02-50,000 | ||

Test Accuracy | 0.01 cc/m2•day•0.1MPa | ||||

Number of samples | 1 | 3 | 3 | ||

Number of main sensor | 1 | 1 | 3 | ||

Test Mode | Single chamber independent | Three cavity Mean | Three-cavity independent sensor | ||

Vacuum error | 0.1Pa | ||||

The degree of vacuum | <10Pa | ||||

Vacuum efficiency | Within 20 minutes, less than 27Pa; | ||||

Test efficiency | Test Time <4 hours, when the transmittance> 5cc / m2.day.0.1MPa | ||||

Temperature range | 5 ℃ -55 ℃ (optional 90 ℃) | ||||

Temperature accuracy | ± 0.1 ℃ | ||||

Humidity | 5 ~ 90% RH (dual airflow humidity law, optional) | ||||

Humidity Accuracy | ± 1% RH | ||||

test pressure | 0.1MPa ~ 0.2Mpa | ||||

Air pressure | 0.1MPa ~ 0.8 MPa | ||||

Test gas | O2, N2, CO2 or other gases | ||||

The carrier gas Interface | ¢ 8 | ||||

Tube diameter | 1/4 " | ||||

Correction mode | Standard film calibration, vacuum sensor outside the school | ||||

Sample thickness | ≤3mm | ||||

Test area | 50cm2, circular (other sizes can be customized) | ||||

Host size | 585 × 640 × 380mm 960 × 550 × 450mm 960 × 550 × 450mm | 585 × 640 × 380mm 960 × 550 × 450mm 960 × 550 × 450mm | 585 × 640 × 380mm 960 × 550 × 450mm 960 × 550 × 450mm | ||

(L × B × H) | 40Kg 60Kg 65Kg | 40Kg 60Kg 65Kg | 40Kg 60Kg 65Kg | ||

Weight (Kg) | 220V AC 50HZ | ||||

Standard Configuration

Item No. | Name | quantity | Model | Unit | Note |

1 | Test Host | 1 | PKT-BSG-11A/31J/33D | set | Includes: vacuum sensor systems, pressure sensors, pneumatic control systems, environmental control systems, communication systems, display and control systems. |

2 | High vacuum pump | 1 | VRD-4 | set | Vacuum capability: 2Pa |

3 | Professional testing software | 1 | G-Vseries | set | 1 Operating System Requirements: Windows 2000 or XP above; |

4 | Communication Cable | 1 |

| pcs | 2 Hardware Requirements: Memory 1G, 80G hard drive or more. |

5 | Vacuum pipe | 1.5 | 1/4” | Meter | Standard RS232 communication cable, length 2m |

6 | Gas hose | 2 | Diameter 8mm | Meter | United States |

7 | Decompression valve | 1 |

| only | 50cm2 sampler, cut the sample |

8 | Disc sampler - sample | 1 |

| set | Dow Corning |

9 | Sealing grease | 1 |

| only | USB1.1 extension cable, length 1m. |

10 | USB | 1 |

| Article | Includes: vacuum sensor systems, pressure sensors, pneumatic control systems, environmental control systems, communication systems, display and control systems. |

Optional | Conversion line | 1/3/3 |

| set |

|

User prepare | Bottle bag test fixture | 1 |

| set | PKT-BSG-11AOptional, other models as standard |

Test gas bottles (oxygen, etc.) |

|

| |||