Filter Integrity Tester

- Products

- Petroleum & Oil Testing

- Tablet Drug Tester

- Refrigeration & Cryogenic

- Life Sciences

- Laboratory

- Spectrometer

- Spray Dryer

- Rotary Evaporator

- Reactor

- Sterilizing & Cleaning

- Water Quality Analyzer

- Chemical Analysis

- Physical Testing

- Centrifuge

- Pathology Equipment

- Optical

- Ultrasonic Homogenizer

- Packaging Testers

- NDT

- Agriculture & Food

- Hazardous Chemical Detection

- Fusion Machine

- Testing Chamber

- Filter Integrity Tester

- Industry Testing Device

- Featured

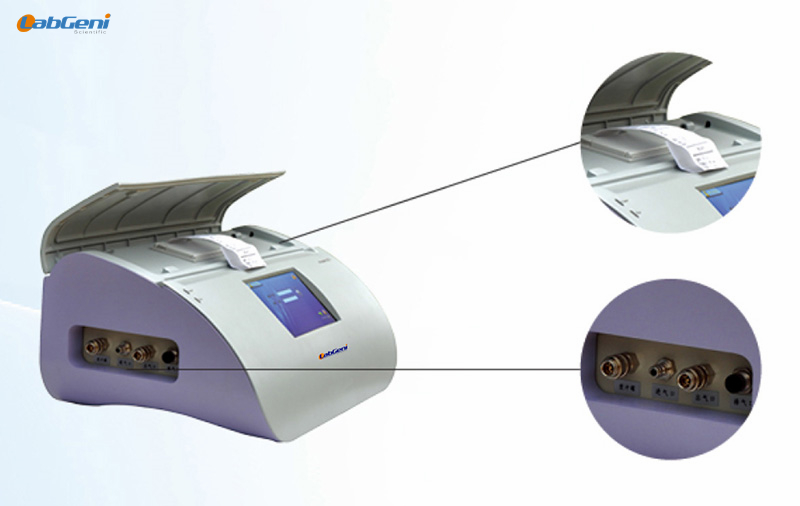

Filter Integrity Tester

FIT-6.0

FIT Serials Integrity Tester are designed for testing integrity of filters and filter systems . The test meet to verify the sterilizing filter in the FDA, the State Pharmacopoeia and GMP specification requirements.

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

More info Related Download

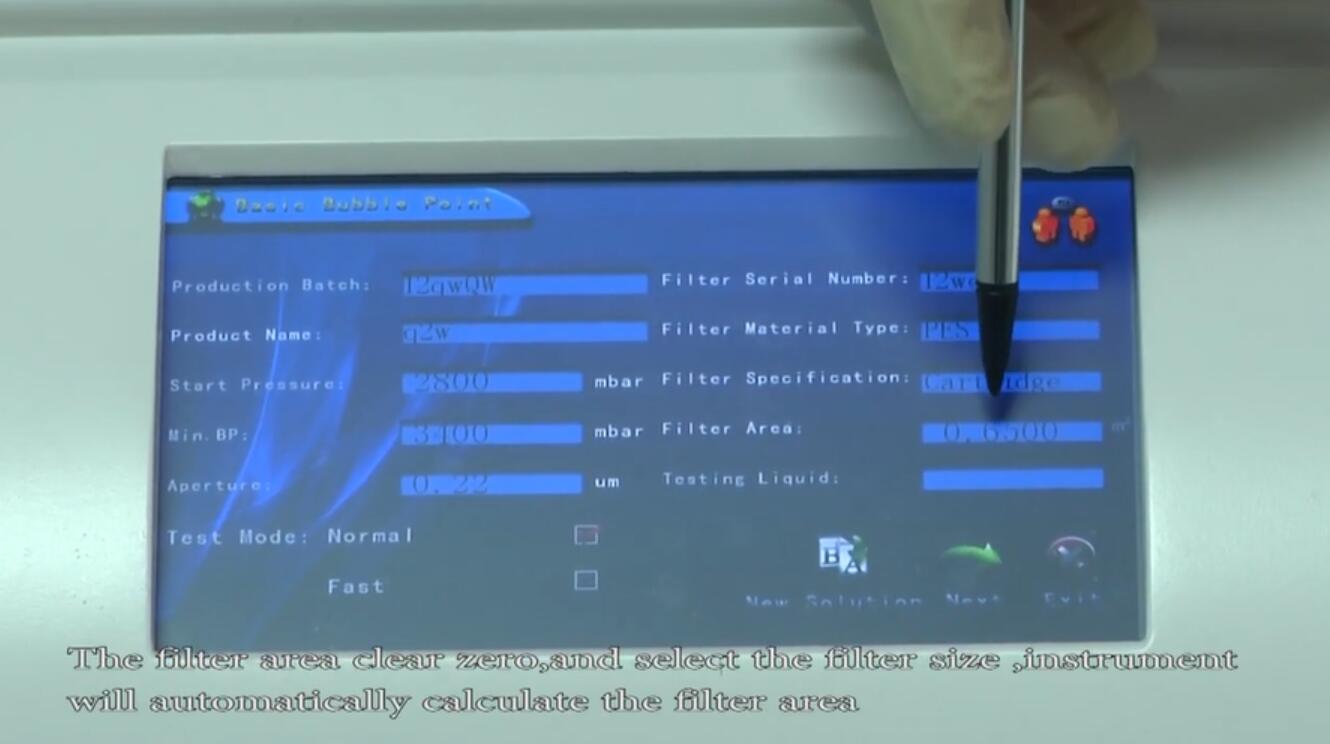

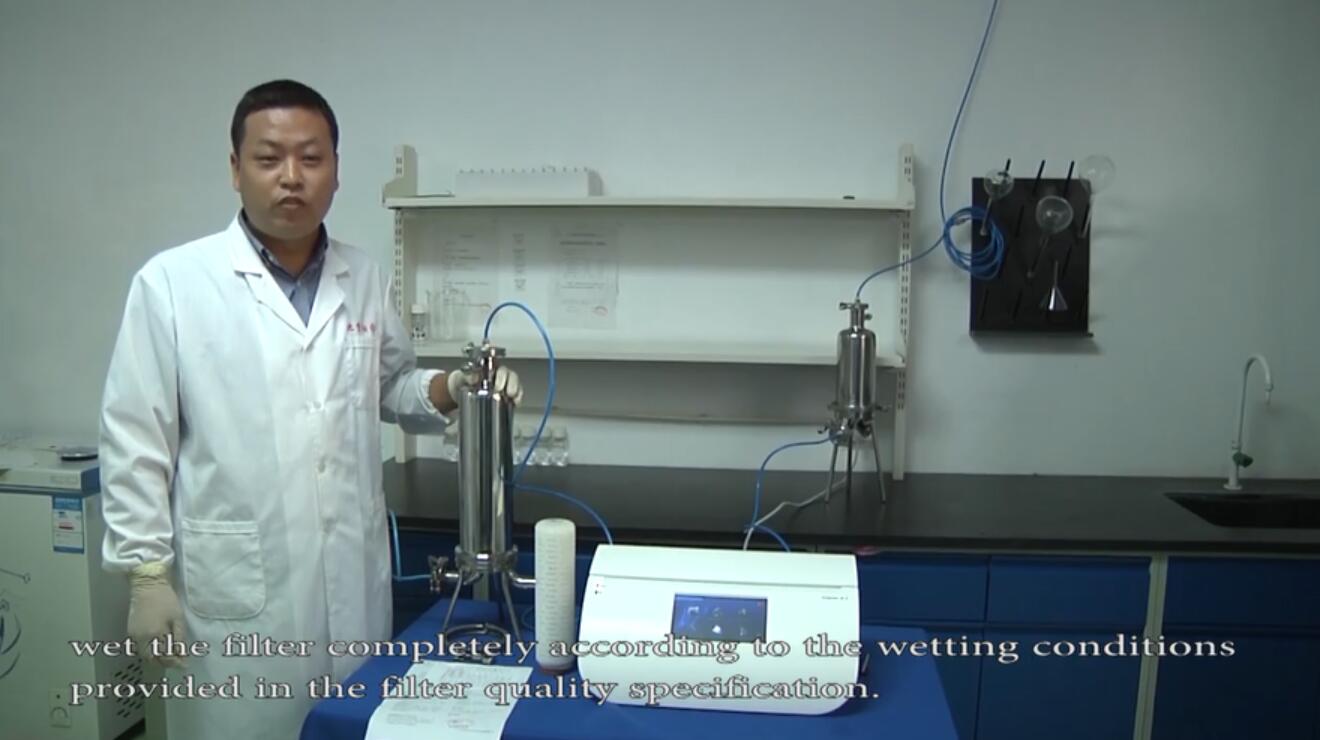

FIT Serials Integrity Tester are designed for testing integrity of filters and filter systems . The test meet to verify the sterilizing filter in the FDA, the State Pharmacopoeia and GMP specification requirements. The FIT-6.0 Integrity Tester is compact,handy to use, and fully automated integrity test instrument, which performs bubble point, diffusion, enhanced bubble point, and water-based test for hydrophobic filters on a wide range of filters. The first domestic launch of integrity test for ultrafiltration membrane, to meet different customer needs.

Brief Description

- Automatic filter infiltration procedures to ensure filter fully infiltration, and it will launch the flow test, will not affect the downstream aseptic, to meet the requirements of on-site testing.

- Advanced data processing technology: the instrument acquisition of the changing apparent diffusion flow and data flow in real-time for analysis diffusion, viscous flow model, which can accurately identify the filter bubble point value so that the membrane filter bubble point test results have a good relevance with real bacterial interception test.

- The instrument get the actual diffusion flow value by measuring the filter upstream volume, and can test water-based test for hydrophobic filters on-site so that solving the problem of residual organic solution invasion.

- With large capacity data storage, the instrument can plug an external SD card storage test results and curve, and can be connected to the PC to achieve unlimited storage.

- Instrument uses advanced algorithms make the instrument more stable and more accurate which is one percent.

- The gas inlet unit of the instrument adopts full automatic digital control, and the whole test process does not need adjust the gas inlet valve manually.

- we designed specially for the large capacity filter, which ensures that the accuracy will not change when the large capacity filter testing.

- The core part of the instrument are imported abroad, and we considered the safety of the operation details when we designed it, and all aspects safety of the operations process handled under the premise of ensuring the basic electrical safety and mechanical safety.

- With English letter and digital entry, the instrument is convenient for customers to directly enter the different batch number, compliance with the new guidelines of GMP.

- Compatibility: built-in parameters being of good compatibility with Millipore, Sartorius and Pall.

Main features

- The newest hardware circuit , advanced digital sensor ensure the test accuracy .

- The industrial –grade dual core make the instrument fast and reliable.

- The tester adopts a simple and convenient "reservation scheme", truly realized A “key to complete the program”.

- Detailed test data and complete test curve to provide users with an objective analysis report as any format you want such as Word、Excel or PDF of the A4 paper.

- The scientific electronic signature and classification to distinguish the responsibility easily, and to prevent false operation.

- Rich data interface, except the standard digital and analog interface(RS232/USB), also customized according to the client needs of a variety of industrial bus and analog control end.

- Independent R & D team could provide the design of a specific program.

- Strong professional and experienced C&S team could offer considerate、 sinere service and technical support.

Utility Range

- Disc Membrane:Φ25mm-Φ300mm;

- Standard Cartridge:2.5″- 40″

- Capsule & Mini Cartridge

- Air filter test :2.5″- 40″

- Ultrafiltration membrane

Demo video

Specifications

| power | 170-240VAC,50/60Hz, 120W |

Maximum working pressure | 10000mbar(150psi) |

Minimum working pressure | 100mbar(1.5psi) |

Dimensions | 280mm(length)X450mm(Depth1)X190mm(Height) |

Test pressure | 100-8000 mbar |

Test function | Manual bubble point test, basic bubble point test, enhanced bubble point test, pressure holding test, diffusion flow test, water immersion test |

Test accuracy | D:±4% ; BP: ±50mbar |

Working condition | Temperature: 5℃-+40℃;Moisture:10±80% |

Test time | Upstream volume test : 5min±2min; |

Checklist print | Input parameters & output data and result, auto/manual printing |

History record | No number limit record store, and support for SD card and USB disk to export data |

LCD | 7″ high definition color touch screen |

Series I/O type | RS232, USB drive |

Language of menu | English |