Fusion Machine

- Products

- Petroleum & Oil Testing

- Tablet Drug Tester

- Refrigeration & Cryogenic

- Life Sciences

- Laboratory

- Spectrometer

- Spray Dryer

- Rotary Evaporator

- Reactor

- Sterilizing & Cleaning

- Water Quality Analyzer

- Chemical Analysis

- Physical Testing

- Centrifuge

- Pathology Equipment

- Optical

- Ultrasonic Homogenizer

- Packaging Testers

- NDT

- Agriculture & Food

- Hazardous Chemical Detection

- Fusion Machine

- Testing Chamber

- Filter Integrity Tester

- Industry Testing Device

- Featured

More info

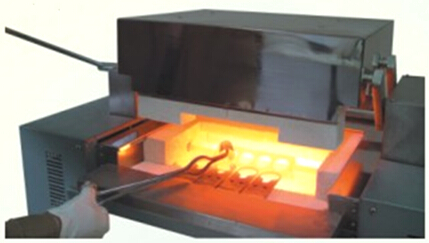

Currently, powdered samples for X-ray fluorescence analysis are usually directly pressed into sample pieces. But that kind of sampling has become a major error factor impacting the precision and accuracy of the element analysis due to the granularity effect, mineral effect and segregation effect of the sample pieces. The bead fusion method can eliminate the granularity, mineral and segregation effects of the samples, and can reduce the absorption and enhancement effects between the elements in the sample, and hence evidently increase the precision and accuracy of the analysis. This bead fusion method is a perfect sampling method for ICP, AA, as well as for indissolvable samples in wet chemical analysis.

- Four samples fused simultaneously, with auto-shaking and auto control

- Auto control means the melting, shaking and standing steps are all precisely repeatable

- Large screen display; auto-alarm and automatic power switching off for overcurrent and overheat

- Customizable heating process, with several heating programs preset

Features

- Applies CPU microprocessor and PID control technique, large screen Chinese display, and menu operation

- Heating with double helix silicon carbide rod; temperature measured with platinum-rhodium thermocouple

- Up to 4 samples can be fused simultaneously (maximum 6 samples if required by user)

- Up to 10 customized heating programs can be preset; within the programs, the heating process, the temperature increase speed, the final temperature, the shaking time, shaking amplitude, and shaking speed of the crucible stool, the cooling time, whether to use fans, the air flow, and so on, all can be preset.

- Automatic control in all the process except for the filling of the fusion sample, enabling the sameness and homogeneity of the sample; all samples are uniformly the same except for the differences in composition

- The bracket of the crucible and the mould are made of high temperature alloy, which guarantees no chemical reaction in high temperature

- Chain wheel lever structure is used in the opening device of the cover of the fusion room, trouble-free for user operation

- With minimum start temperature alarm and power switch-off protection when the cover of the fusion room is open

- Automatically switching off power and setting alarm for overcurrent and overheat; independent temperature measurement thermocouples are used for overheat protection and heating control; together with the heating control circuit, they can form treble protection of the system and can make the power switch-off protection for overheat more reliable.

Specification

- Heating unit: 3 pieces of double helix ,single-end, silicon carbide rod

- Maximum Temperature: 1250°C,continuously adjustable

- Temperature measurement unit: 2 pieces of platinum-rhodium thermocouple, with maximum measurable temperature 1600°C

- Capacity: 4 samples simultaneously (maximum 6 samples if required by user)

- Wattage: 6kw

- Power supply: 380-415V,50-60Hz, three phase

- Dimension(Height ×Width × Depth): 500mm×1217mm×500mm

- Weight: 115kg