Interfacial Tension Meter

- Products

- Petroleum & Oil Testing

- Tablet Drug Tester

- Refrigeration & Cryogenic

- Life Sciences

- Laboratory

- Spectrometer

- Spray Dryer

- Rotary Evaporator

- Reactor

- Sterilizing & Cleaning

- Water Quality Analyzer

- Chemical Analysis

- Physical Testing

- Centrifuge

- Pathology Equipment

- Optical

- Ultrasonic Homogenizer

- Packaging Testers

- NDT

- Agriculture & Food

- Hazardous Chemical Detection

- Fusion Machine

- Testing Chamber

- Filter Integrity Tester

- Industry Testing Device

- Featured

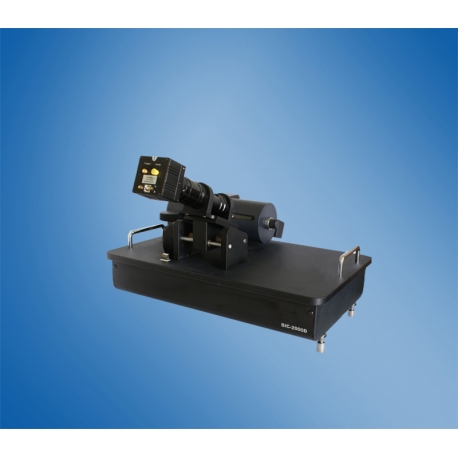

Spinning drop interfacial tension meter

SIT2000D

Based on SIT2000C type spinning drop interfacial tension instrument, it is developed by the improvement of the classic plug-in injector pipe system, anti-corrosion stainless steel heating system and image acquisition .

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

More info

Description

Based on SIT2000C type spinning drop interfacial tension instrument, it is developed by the improvement of the classic plug-in injector pipe system, anti-corrosion stainless steel heating system and image acquisition .This product is easier to operate and more stable .The main application areas are: oil EOR (chemical flooding) indoor study and site monitoring; study of surfactants, detergents, emulsions and foams; research fuel oil, lubricants, paints, inks and coatings; pharmaceutical, paper research products, photographic materials, pesticides and so on.

Feature

1. Improved quartz glass instrument pluggable manner, spring thimble against the sample tube, automatically pop up when removing the sample tube easily broken. When injecting the sample into the test again, easier to clean, more convenient operation. Since the inner sleeve made of stainless steel and stainless steel rotor, expansion coefficient of convergence is conducive to temperature conductivity, the material is not susceptible to corrosion and rust, high concentricity, easier to maintain sample tubes horizontally stable, easy to shake.

2. The whole process PC computer and pre-SBC is controlled by the use of computer technology to collect spinning drop multimedia video images to analyze, calculate, has a very good maneuverability and repeatability.

3. Using the latest precision LED control technology while updating the high-speed acquisition and trigger mode CCD image acquisition under low-speed and high-speed rotation conditions are not flashing screen, the image is sharper edge interface, useful for analyzing oil samples turbid fine features.

4. The master program is Windows interface, easy operation, the image as a standard BMP file that can be stored in print. The program uses the world's leading computing technology interfacial tension measured value, simply press the "test", our software automatically controls the speed camera, save the images to calculate interfacial tension value, showing the measured values, the process without human intervention, so as to effectively avoid the human factors on the measured value. You can record the value of interfacial tension with time, speed, temperature changes and all measured values are stored in the database, and export directly to EXCEL documents to be displayed in real-time graph of the measured values. User-friendly software design, powerful database management manage all test data.

5. interfacial tension measurement wide range, from 10-6mN / m to 100mN / m, across eight orders of magnitude for the whole range of the tension gauge.

6. The use of US imports PITTMAN high-speed motor, servo motor control with complete system upgrades and better compatibility, speed control up to 10,000 rev / min (also choose higher speed 14,000 rpm / min motor), precision can control the speed of ± 5 rev / min, motor encoder control points up to 500 points / turn, more accurate, more convenient manipulation. Increased precision arc pendulum platform and one-dimensional focusing platform that enables high measurement precision, while providing a number of stalls magnification, hair width can be enlarged to over one hundred pixels, greatly improve the measurement accuracy of ultra-low interfacial tension.

7. With electric heating temperature control system, capable of constant temperature experiments. The instrument uses a precise PID temperature control technology, heating assembly with a new corrosion resistant stainless steel design, fast heat conduction and easier to uniformly heat the sample tube not need to meet other temperature control equipment, instrument can also choose a super bath temperature control, two temperature control system compatible.

8. Low noise electric viewfinder mechanism interface button operation, simple and convenient. Three leveling design makes it easy to control droplets in the range of available window. Optional SIT2000B classic type rotary swing mechanism, the balance in favor of drop placement. More high-end automatic optional viewfinder, the testing process no longer need to manually adjust the position of the droplet, easier to operate.

9. Fusion new technology industrial touch screen and networking technology, the Internet keeping with the times + innovative products.

Technical Specifications

1, Measurement range: 100 ~ 10-6mN / m;

2, Temperature range: 5 ℃ ~ 95 ℃ (PID precision temperature control or electric water bath temperature);

3, Temperature display range: 0 ~ 99.9 ℃;

4,Temperature display accuracy: ± 0.1 ℃;

5, Reading range: 0 ~ 6mm (inner diameter to provide 2mm, 4mm high purity quartz tube);

6, Communication interface: USB interface or COM interface;

7, Image acquisition mode: USB standard camera flash trigger mode or analog acquisition mode;

8, Video Speed: 60 frames / sec;

9, Speed: 1,000 to 10,000 rev / min, speed control accuracy of less than 0.1% accuracy can be controlled speed of ± 5 rev / min;

10Reading measurement accuracy: 0.001mm;

11, The results of the program window: Image and data window can be displayed simultaneously;

12, Data storage: Each measurement data to generate a folder, ready for data detection, real-time or time taking pictures.

13, Manual tilt adjustment mechanism (optional)

14, Like homing function (optional)

15, Ultra-high speed 14,000 rev / min motor (optional)

16,120 frames / sec high-speed camera system (optional)

17, Real-time LAN uploading data (optional)

18, Contact angle measurement function (optional)

Standard Components

1, the instrument host (excluding matching computer): 1unit

2, industrial imaging system 1 set;

3, RS-232 serial line 2 pcs /

4.USB data line 1 pcs

5, power line 1pcs;

6, a syringe with a needle length 10cm 5 pcs

7, the inner diameter of 4mm sample tube 4pcs;

8, the inner diameter of 2mm sample tube 4pcs;

9, centrifuge tubes sealed with a plug 5 sets;

10, the host rotating shaft pressure cap 2pcs;

11, instrument calibration standard tube 1 pcs