Liquid Handling Instrument

- Products

- Petroleum & Oil Testing

- Tablet Drug Tester

- Refrigeration & Cryogenic

- Life Sciences

- Laboratory

- Spectrometer

- Spray Dryer

- Rotary Evaporator

- Reactor

- Sterilizing & Cleaning

- Water Quality Analyzer

- Chemical Analysis

- Physical Testing

- Centrifuge

- Pathology Equipment

- Optical

- Ultrasonic Homogenizer

- Packaging Testers

- NDT

- Agriculture & Food

- Hazardous Chemical Detection

- Fusion Machine

- Testing Chamber

- Filter Integrity Tester

- Industry Testing Device

- Featured

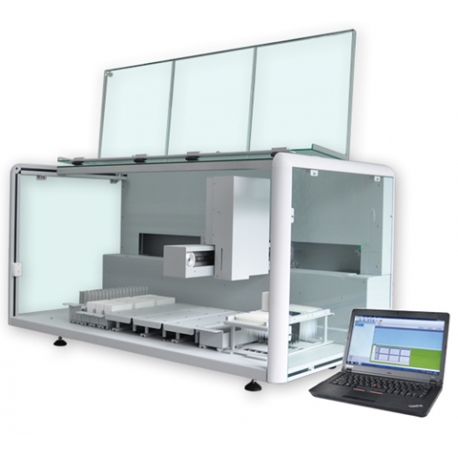

Liquid Handling Workstation for Laboratory

CLS-3

The CLS-3 Series of automated liquid handling systems has been designed to satisfy the increased demand, technical requirements and budgets for liquid handling systems in today’s modern laboratories.

>

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

More info

Main Features

1. Pipetting arm moves X, Y, Z axes freely.

2. Multi-channel aspiration and dispensation, each channel with independent liquid level detection

function.

3. Free loading, ensuring uninterrupted handing.

4. Powerful software capability, supports graphical programming.

5. Flexible configuration of hardware resources, supports multi-machine pipeline operation

6. High-resolution color LCD touch screen enables the operation to be easier and move convenient.

Introduction

The CLS-3 Series of automated liquid handling systems has been designed to satisfy the increased demand, technical requirements and budgets for liquid handling systems in today’s modern laboratories.

Automation is revolutionizing the way scientists do research - maximizing accuracy, precision and throughput while minimizing time and consumable costs. However, the prevalent thought that automated systems are expensive, complicated, and space-consuming leave many scientists unwilling or unable to maximize the potential of their work.

The CLS-3 automated liquid handling system employs two types of robotic arm function: liquid handling and plate transport. With these two types of arms and various liquid handling modules, the Utraoliquid handling series specifications can be customized to match the users liquid handling needs.

The CLS-3 liquid handling modules allow for a wide range of volumes extending into nanolitre volumes. The reliable and reproducible nanopipettor is highly useful for low volume aspiration and dispension operations. The ReagentDrop module presents high-speed dispense functions from on-line reagent bottles.

Furthermore, the CLS-3 liquid handling series offers specialized liquid handling accessories. Aurora offers specialized combination heads bulk dispensing from a single liquid handling module. The large volume range allows for the notion of parallel dilution whereby a dilution scheme is created directly using nanolitre capabilities. Parallel dilution is more accurate than the traditional serial dilution method.

Application Workstations

The CLS-3 sample liquid handling workstation can be configured to accommodate protocols with diverse needs. Whether a workflow requires accurate temperature control, precise handling of small volumes, or customized liquid handling, the workstation provides an exceptional solution. The platform has the competence to exceed expectations and the flexibility to handle a wide array of bench work. Numerous methods that are widely used have been automated with different formats of the Utrao1100 workstation, and the system remains customizable to accommodate unique needs.