Micro Laser Diffraction

- Products

- Petroleum & Oil Testing

- Tablet Drug Tester

- Refrigeration & Cryogenic

- Life Sciences

- Laboratory

- Spectrometer

- Spray Dryer

- Rotary Evaporator

- Reactor

- Sterilizing & Cleaning

- Water Quality Analyzer

- Chemical Analysis

- Physical Testing

- Centrifuge

- Pathology Equipment

- Optical

- Ultrasonic Homogenizer

- Packaging Testers

- NDT

- Agriculture & Food

- Hazardous Chemical Detection

- Fusion Machine

- Testing Chamber

- Filter Integrity Tester

- Industry Testing Device

- Featured

More info

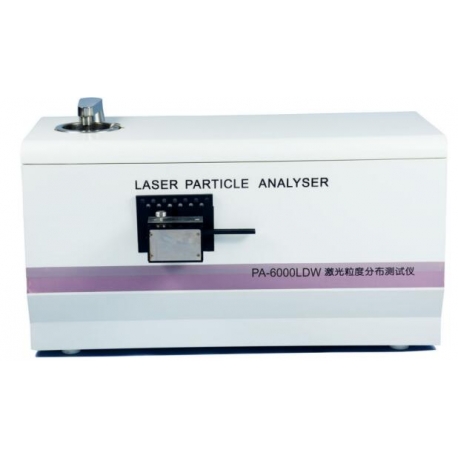

PA-6000LDW is a new type particle size analyzer instrument integrating both dry and wet test. In addition to powder liquid suspensions PA-6000LDW particle analyzer can measure dry pharmaceuticals and magnetic powders as well as emulsion particles. PA-6000LDW is a highly intelligent particle size analyzer working with fast speed, easy operation and good repeatability and has become a good choice for many industries.

PA-6000LDW works with both liquid and dry dispersing system:

—The dry system includes host,, auxiliary equipment( including vacuum, waste powder collecting can, air purification tank) and quiet air compressor.

—The liquid system includes ultrasonic dispersion, mechanical agitation, circulation etc.

—Just click the mouse to shift between liquid and dry without manually replacing the device in order to secure the accuracy and repeatability.

Applications:

Dry powder or emulsion particle size distribution analysis including Ferrite, NdFeB, hard magnetic powder, soft magnetic powder, cement, cobalt powder, electronic materials, pesticides, pigments, pharmaceuticals, ceramics, cosmetics, paint and coating, food, calcium carbonate, talc, kaolin, alumina, rare earth, catalyst, blowing agent, refractory material, graphite, etc.

Features:

1. Integrated dry, wet testing two functions, which not only can detect neodymium iron boron and other magnetic materials, powder, cement, etc.which can not dispersed in the water , and also can test a variety of dry powder, emulsion slurry.

2. Dry testing or wet testing, without the need to replace any part ,under the computer controlling ,direct key conversion is completed, easy to use.

3. Instrument include host, auxiliary engine, oil-free silent compressor 3 large parts, compact and reasonable, nice shape. Auxiliary engine is an accessory of dry testing, containing separation filter purifier, dust removal system, dust storage tank. Dry sampling decentralized, air intake, testing, collection and other operations are automatically controlled by the computer to complete, easy to operate.

4. The circulatory system, ultrasonic dispersion, the sample cell for wet testing are set in the host, good seal and anti-interference ability, effective in preventing dust pollution ,before the test, the computer is automatically controlled to zero.

5. Dry testing adopts unique design of dry dispersion system (patent), the design of the dry spray gun in the automatic test program to create a particle fully dispersed their own rotation, the particles collide with each other, the collision of particles and the wall opportunities to ensure that particle is the monomer state during the measurement.

6. Dry test, the sample into the injection site, just press the control switch, you can test several times in a row, and save the test results.

7. Configure oil-free mute air compressor, with low noise, small size, power consumption, simple maintenance, safety and durability, long operating time and other advantages.

Specifications

Principle | Full course Mie scattering theory comply with ISO 13320 |

Measuring range | 0.02~2,000µm |

D50 error range <±3%(National Certified Reference Material) | |

Light source | Laser diode 632.8nm 3mw >20,000h |

Light path | Parallel light path design comply with ISO13320 and ISO13321 |

Test course | Full course without any shift during test |

Detector | Multi-element-silicon detector: |

128 photo cells arranged in 3-D position maximize the detection angel up to 165° | |

Test Method: Wet and Dry Measurement | Dry: Put the sample in the dry tank and click on dry test, the unit automatically open/close the air supply, test, collect sample, whole operation finishes under computer control within 2 minutes. Wet : Click on liquid test, the liquid tank is filled up automatically, the system prompt feeding powder, add about 1 gram of powder into the liquid cell, the dispersion, agitation, circulation and cleaning finish under computer control within 2 minutes. |

Dispersion | Dry : Unique vacuuming device (patented) done by cooperation of compressor and vacuum, short dispersing time. |

Wet : Ultrasonic, agitator and sample cell are integrated, compact design, short dispersion time | |

zAgent | Dry : Air |

Wet : Tap water, distilled water or other specified agent | |

Sample weight | Variable suspension volume with the wet dispersion unit: |

1gram or up to scores of grams dependent on the sample property and size | |

Test software | Windows |

Result output | Table and curve of particle size distribution, D10, D50, D90, D97, averaged particle size and specific surface area. etc |

Power | AC220V 50Hz /110V 60 Hz |

Environment | Clean, temperature 0-40℃ |

Size (L*W*H) | Analyzer:860mm×420mm×500mm Dry test auxiliary machine:660mm×320mm×900mm |

Standard analyzer configuration

Item name | Unit | Qty | Remark | |

1 | PA-6000LDW laser particle size analyzer host | PC | 1 | Including ultrasound, blender, circulation and so on |

2 | PA-6000LDW laser particle size analyzer auxiliary | PC | 1 | Including dust, dust storage tank, air purification tank |

3 | Oil-free mute air compressor | PC | 1 |

|

4 | Special granularity analysis software | SET | 1 |

|

5 | Instrument operating instructions | PC | 1 |

|

6 | Factory inspection report, test certificate, certificate | PC | Each 1 |

|

7 | power cable | PC | 2 |

|

8 | Serial line, control dedicated line | PC | Each 1 |

|

9 | Sample tank | PC | 2 |

|

10 | Air compressor intake pipe, dust pipe | PC | Each 1 |

|

11 | Screwdriver, brush | PC | Each 1 |

|

12 | Silicone tube | PC | 3 | Backup |

13 | Pulley rubber ring | PC | 10 | Backup |

14 | Inlet valve | SET | 1 |

|

15 | Intake pipes, drains | PC | Each 1 |

|

16 | Sealing pads | PC | 1 | Backup |

17 | Dispersant | Bottle | 1 |

|

18 | standard sample | Batch | 1 |

|

19 | Dustproof glass | PC | 1 |

|

20 | Fuse | PC | 1 |

|

21 | Mixing belt | PC | 1 | Backup |

22 | Sampling spoon | PC | 1 |

|

23 | Silk cloth | Bag | 1 |