Particle Image Analyzer

- Products

- Petroleum & Oil Testing

- Tablet Drug Tester

- Refrigeration & Cryogenic

- Life Sciences

- Laboratory

- Spectrometer

- Spray Dryer

- Rotary Evaporator

- Reactor

- Sterilizing & Cleaning

- Water Quality Analyzer

- Chemical Analysis

- Physical Testing

- Centrifuge

- Pathology Equipment

- Optical

- Ultrasonic Homogenizer

- Packaging Testers

- NDT

- Agriculture & Food

- Hazardous Chemical Detection

- Fusion Machine

- Testing Chamber

- Filter Integrity Tester

- Industry Testing Device

- Featured

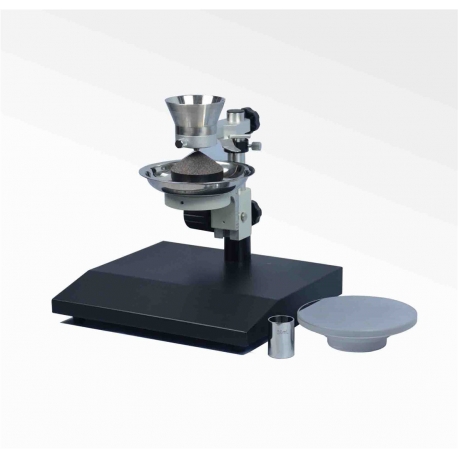

Powder characteristics tester (repose angle, fluidity, bulk density test)

PCT-A3

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

More info

In the use of various powders, the powder's particle shape, fineness, particle size distribution and cohesiveness will directly affect the quality of the product. PCT-A3 powder characteristics tester, with reference to national standards, has two sets of unique A stacking powder discs and B stacking powder discs. The two test plates A and B are equipped with the test of fluidity, angle of repose (angle of repose) and loose density. The test results are saved and viewed by computer records, and easy to print.

A stacking powder disk keeps the principle of national GB6521-86. It adopts the traditional method of powder injection. It passes through the funnel from a fixed height and falls freely on a horizontal metal plate with eight graduations to form a cone. The angle between the face and the bottom is the angle of repose (the angle of repose).

B stacked powder disk uses a new test method, which is more convenient to use. The test result is high in accuracy. That is, an upper disk is set at the center of the funnel. When the powder flows out of the funnel, it accumulates into a stable cone, just covering the Small plate, and then directly look at the scale on the lifting base, read the stacking height of the powder. Need to know the loose density data, just put the matching 30ml standard sample powder cartridge of the instrument on the A or B disk, you can know the loose density data.

Angle of repose (angle of repose) test principle:

With reference to the international standard ISO902-1976, the principle of national GB6521-86. With no vibration, the sample passes through the funnel from a fixed height and falls freely on a horizontal metal plate with eight graduations to form a cone. The angle between the cone and the bottom of the cone is the rest angle (rest angle). The repose angle is generally calculated from the average diameter and height of the obtained cone sample.

Angle of repose test operation method:

The volume of the powder pile is controlled within a certain range, and the powder ceases to flow out and accumulates into a stable cone. The 8 radius data of the pile on the loading platform is entered into the computer, and the average radius of the pile and The height of the stockpile gives the repose angle of the powder. Results can be saved or printed directly. See below

Powder flowability test principle:

With reference to the international standard ISO4490-1978, the principle of national GB1482-84. It is suitable for determination of powder flowability.

Liquidity test operation method:

The outlet at the bottom of the funnel was blocked, and 50 g of the sample was weighed and poured into the funnel. When the small hole in the funnel was opened, the timing was started. Once the powder in the funnel had flowed out, the timing was stopped immediately, and the time required for all the samples in the funnel to flow was recorded. Measure at least 3 times, and take the arithmetic mean as the final result to obtain the powder flowability. See below

Loose density test principle:

With reference to the international standard ISO903-1976, the principle of national GB6522-86. The sample falls freely from a fixed height without vibration, and is filled into a fixed container of known volume, and the bulk density is calculated from the mass and volume of the sample.

Loose density test operation method:

The center line of the funnel coincides with the center line of the standard measuring cylinder. Pour the sample into the funnel and flow into the standard measuring cylinder. When the sample forms a cone on the top of the standard measuring cylinder and starts to overflow, stop adding samples, and then use a straight steel ruler along the standard measuring cylinder Gently scrape off the excess sample from the upper edge. Normally, two samples are measured in parallel, and the arithmetic average is taken as the final result.

Product configuration:

Name | Unit | Number | Note |

Instrument host | station | 1 |

|

Stacked powder tray | Each | 2 |

|

Standard measuring cylinder | Each | 1 |

|

Special software (fluidity, bulk density, repose angle calculation software) | set | 1 |

|