Surface Area & Pore Size

- Products

- Petroleum & Oil Testing

- Tablet Drug Tester

- Refrigeration & Cryogenic

- Life Sciences

- Laboratory

- Spectrometer

- Spray Dryer

- Rotary Evaporator

- Reactor

- Sterilizing & Cleaning

- Water Quality Analyzer

- Chemical Analysis

- Physical Testing

- Centrifuge

- Pathology Equipment

- Optical

- Ultrasonic Homogenizer

- Packaging Testers

- NDT

- Agriculture & Food

- Hazardous Chemical Detection

- Fusion Machine

- Testing Chamber

- Filter Integrity Tester

- Industry Testing Device

- Featured

More info

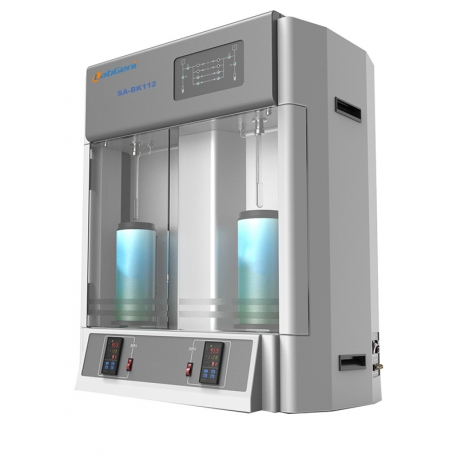

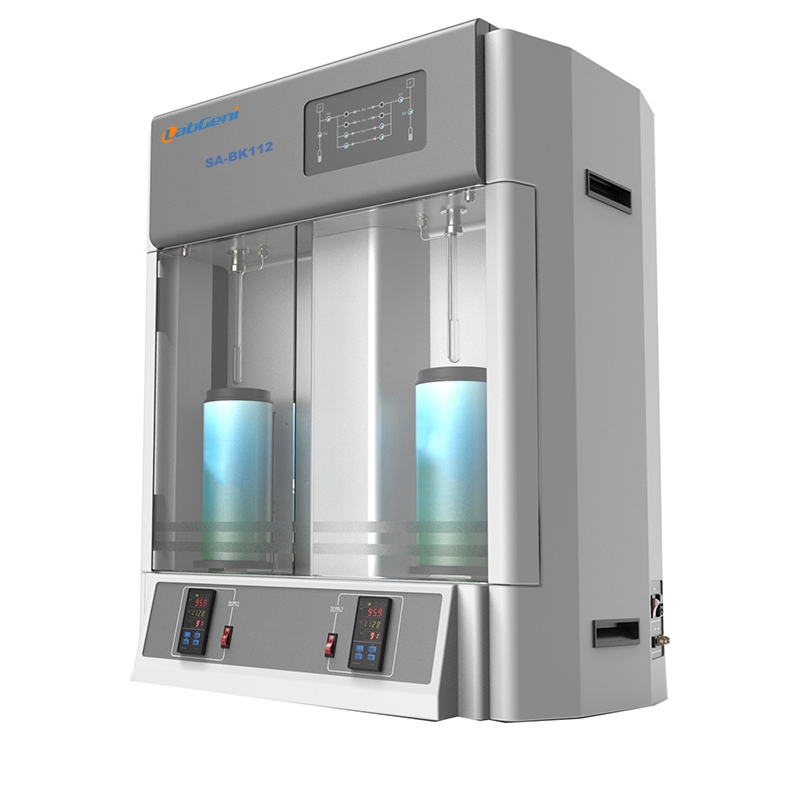

Main function:

BET specific surface area (multi-point, single-point), Langmuir surface area, t-plot method the external surface area; BJH pore mesoporous large pore volume and pore size distribution points

Analysis; t-plot method of microporous total pore volume, surface area measured within; DR method micropore volume determination; MP microporous analysis method; HK method, SF method,

Special Features: (NL DFT method microporous precise analysis), CO2- ice method microporous accurate analysis; true density accurately test; adsorption heat test; average particle size estimate; density input test.

Applications

● Rubber material: carbon black, silica, calcium carbonate, zinc oxide, titanium dioxide, silica, silicon oxide, and other chemical raw materials;

● Battery materials: lithium cobalt oxide, lithium manganese oxide, lithium iron phosphate, graphite, ternary materials, membranes and other positive and negative electrode material;

● Catalyst material: activated alumina, molecular sieves, zeolite and the like;

● Desulfurization and denitrification material: denitration catalyst, denitration titanium dioxide and the like;

● Food Additives: starch, activated clay, bentonite and the like;

● Magnetic materials: iron oxide, ferrite, and manganese tetroxide;

● Environmental protection: activated carbon adsorbent;

● Nanomaterials: nano ceramic powder (alumina, zirconia, yttria, silicon nitride, silicon carbide, etc.), the metal nano powder (silver powder, iron powder, copper powder, tungsten powder, and nickel powder), high nano molecular materials, carbon nanotubes;

● Coal industry: coal, ore, rock, shale gas and coalbed methane;

● Other material: microfiber, porous fabrics, composite materials and soil.

Features and Benefits

●Two test can be performed simultaneously with the bit degassing, degassing highest temperature 400 ℃;

● Multi-point BET surface area test can be done automatically within 30 minutes;

● Liquid nitrogen level control integrated systems and software compensation technology to ensure that throughout the test sample chamber non-uniform temperature field is relatively constant, to ensure the accuracy of the analysis for nitrogen, liquid argon, ice and other cold bath;

● The introduction of foreign advanced technology thermostat clip, equipped with large-capacity vacuum glass liner volatile liquid nitrogen Dewar and anti means test to ensure sustainable for 72 hours;

● Adjustable multi-channel parallel-controlled vacuum system, built-in anti-splash unit, and "Ladder" splash procedures to effectively prevent ultra-fine powders pumping fly, completely avoid contamination of the instrument;

● The instrument control panel has a control valve position indicator, more intuitive experimenter visible control valve operation, user-friendly design;

● Nonlocal density functional theory NLDFT standard configuration model, reached the international advanced level;

● Equilibrium pressure of intelligent control technology, the sample adsorption / desorption equilibrium pressure and automatically determine the data collection, isothermal adsorption-desorption curve test points can be automatically controlled;

● Ethernet data acquisition and processing software to guide the operation, a set of software can control multiple instruments, remote control;

Technical Parameters

Test accuracy: ≤ ± 1.0% (surface area); pore diameter repeatability ≤0.02nm;

Test gas: nitrogen gas of high purity (99.999%), or other gases (such as Ar, Kr, CH4, CO2, etc.);

Test Range: 0.005 (m2 / g) - to unlimited (specific surface area); 2nm-500nm (mesoporous and macroporous analysis); 0.35nm-2nm (micropores routine analysis); total pore volume 0.0001cc / g- to unlimited;

Vacuum system: stainless steel vacuum line system, multi-channel parallel path vacuum, vacuum pumping speed to fine-tune the system patented technology, can automatically adjust the pumping speed adjustment range 2-200ml / s;

Vacuum chamber: the manifold vacuum chamber, modular design, full cryogenic solenoid valve control, do not use pneumatic valves;

Sample tube chuck system: external anti-pumping sample tube fly chuck system, patented technology;

Temperature correction: the use of temperature sensors in real time, accurate and precise test space for the internal temperature was measured and calculated in real time to introduce the theoretical model;

Analysis station: two test sites, two consecutive samples for testing;

Lifting system: two sample test sites in situ has two independent lifting systems, electric control, automatic control and interfere with each other;

Degassing system: vacuum degassing pretreatment system must be the same bit modular design ,, avoid secondary pollution. In situ degassing system: two independent heating mantle, two independent temperature control system can be programmed temperature control, temperature program set up to order 10 order; degassing temperature range of room temperature -400 ℃, accuracy of ± 1 ℃;

Vacuum pump: Adopt external imports two-stage rotary vane mechanical vacuum pump (automatic anti-return oil), you can not use a built-in mechanical pump, avoid prolonged mechanical pump vibrations affect test accuracy, can effectively extend the service life of the instrument.

Ultimate vacuum: ultimate vacuum 4-6.7 × 10-2Pa;

Partial pressure range: P / Po accurately controllable range of 10-4-0.998 can be measured more than 1000 points;

Data control, acquisition and processing system: Compatible with Windows 7 / XP systems, LAN port data acquisition, processing software, the entire testing process equilibrium pressure control, pressure full automatic real-time monitoring data collection and graphical display and automatically saved to the original file, open and preview the entire pressure offline data collection and reporting of test results, may also be post-processed data; a computer, a set of software can simultaneously control multiple instruments;

Instrument Specifications: size, length 60.5cm × width 47.5cm × height 84cm; weight, 56 Kg;

Power source: AC 220V ± 20V, 50 / 60HZ, the maximum power of 300W; current 5A; ambient temperature: room temperature 20 - 25 ℃;

Quality certification: CE certification, the China Association for Instrumental Analysis technical appraisal by experts (provided the original), the country's new product certification, GB / T 19001-2008 quality management system certification, high-tech enterprises

Item No. |

| Accessory Name | Quantity | Price(Yuan) | Note |

1 | Manufacturers | Host SA-BK112 type | 1set |

| Main selection of imported parts 1. Pressure Sensor |

2 | SA-BK112-specific software and drivers | 1set | |||

3 | Liquid nitrogen containers (10L) | 1pcs | |||

4 | Static Dewar | 2pcs | |||

5 | ◆ static quartz sample tube | 10pcs | |||

6 | ◆ sample sample loading funnel V | 6pcs | |||

7 | ◆ quartz mandrel | 4pcs | |||

8 | Valve and fittings | 2pcs | |||

9 | ★ specific surface area of the standard sample | 20grams | |||

10 | Fuse | 5pcs | |||

11 | power cable | 2pcs | |||

12 | Data cable | 2pcs | |||

13 | Seal ring | 6pcs | |||

14 | Stainless steel tee | 1pcs | |||

15 | user's Guide | 1set | |||

16 | Recommended | 10 elevated pure helium (including cylinders) | 1bottle |

| 99.999% |

17 | 40 elevated pure nitrogen (including cylinders) | 1bottle |

| 99.999% | |

18 | Optional | Dell and other computer brands | 1set |

|

|

19 | HP inkjet color printer | 1set |

|

| |

Note | 16-19 items for customers freely selected according to the needs; "◆" for the wearing parts;“★” Consumables, can be used normally more than one year; | ||||