Surface Interface Testing

- Products

- Petroleum & Oil Testing

- Tablet Drug Tester

- Refrigeration & Cryogenic

- Life Sciences

- Laboratory

- Spectrometer

- Spray Dryer

- Rotary Evaporator

- Reactor

- Sterilizing & Cleaning

- Water Quality Analyzer

- Chemical Analysis

- Physical Testing

- Centrifuge

- Pathology Equipment

- Optical

- Ultrasonic Homogenizer

- Packaging Testers

- NDT

- Agriculture & Food

- Hazardous Chemical Detection

- Fusion Machine

- Testing Chamber

- Filter Integrity Tester

- Industry Testing Device

- Featured

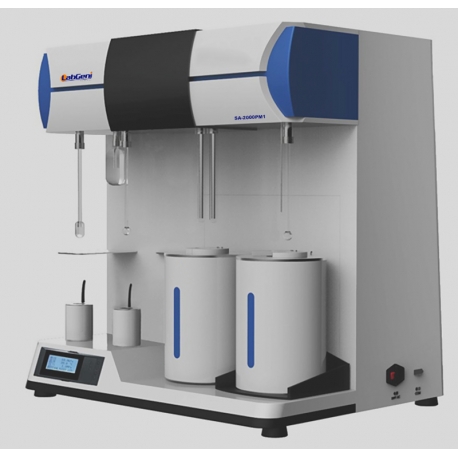

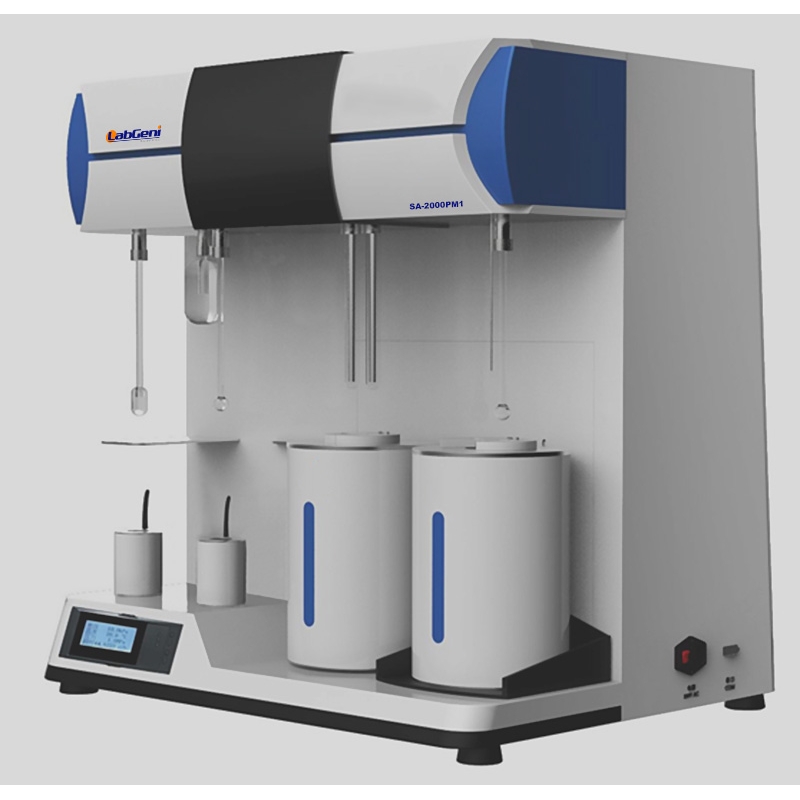

High Performance Surface Area and Pore Size Analyzer

SA-2000PM

SA-2000PM series of specific surface area and pore size analyzer can get specific surface area of the material ,total pore volume, pore size distribution and adsorption-desorption data, especially for the pore size distribution of the microporous material to give a more accurate test results,

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

More info

Product Description:

SA-2000PM series of specific surface area and pore size analyzer can get specific surface area of the material ,total pore volume, pore size distribution and adsorption-desorption data, especially for the pore size distribution of the microporous material to give a more accurate test results, the instrument equipped with a three sets of pumps: imported turbo molecular pump and two mechanical pumps and high-precision pressure sensor ,can accurately test below 0.7 nm pore size distribution, direct comparison with similar imported products, it is the first choice for activated carbon, molecular sieves, MOF and other porous nano materials

Technical Features and advantages

- BEST multiple manifold system

- Original BEST multiple manifold system, the control valve overall integrated design, modular assembly, the limit will be reduced to a vacuum line, the dead space volume to a minimum, the instrument seal more than 5 times, reaching the level of imports of high-end equipment, greatly improved the stability and accuracy of the instrument; the various parts of the gas system integrated modular assembly, which greatly reduce the failure rate, significantly enhance the stability of the instrument;

- Integrated modular assembly line

- Fully modular manifold structure in the true sense, the entire manifold block module from stainless steel processing, without any thread sealing or welding and the line pressure port, the complete elimination of leakage point, the entire cavity leak rate of less than 10- 10Pa * m3 / s;

- completely independent vacuum degassing and Analysis System

- Instrument is equipped with two independent vacuum systems, both degassing system and analysis system independent of each other; the degassing system with separate two-stage mechanical vacuum pump, the ultimate vacuum reached 10-2Pa, analyze position with a separate two-stage mechanical vacuum pump imported from Germany + turbo molecular pump, the ultimate vacuum reached 10-6Pa; two independent vacuum system that is composed of three pumps to improve the efficiency of the test, and really eliminate the mutual impact analysis and degassing at the same time between when, and by avoiding a vacuum system and the pollution problems;

- hardware combined with software, the complete elimination of elutriation boiling

- Dust pollution vortex principle hardware original equipment, in combination with software anti-fly program drawn eliminate volatile samples at high vacuum elutriation boiling phenomenon caused by the system so as to avoid the drop after airtight volatiles contaminated piping valves Happening;

- Optional processing mode

- It has the domestic first normal mode of sample preparation and molecular replacement mode in two modes;

- prevent cup of liquid nitrogen accidental fall

- The only domestic cup liquid nitrogen to prevent accidents "safe drop" smart control mechanism, completely avoid the unexpected drop in the cup of liquid nitrogen gas is expanded so that the risk of sample tube burst;

- Vacuum pump automatic start and stop

- Optimization of pump start-stop management system, during the test has been running without a vacuum pump to reduce noise and prolong the life of the vacuum pump;

- automatically save the current data when power off

- Superior stability, even if unexpected power outages, broken, without losing the current data and the experiment continued recoverable;

- sealing self-test

- Advanced intelligent self-test process, intelligent judgment sample tube is installed, the jacket tubes are tightened for leaks;

- user-friendly interface

- Clear image of graphical control interface, and can perform all operations on the hardware control interface;

- high intelligent mode

- Interactive Data processing software enables automatic operation of the instrument, long experiment entirely without human duty, report content can be customized according to user needs.

Model | SA-2000PM1 | SA-2000PM2 |

Sample test | 1 sample | 2 sample |

Test theory | Adsorption and desorption isotherms; | |

Test accuracy | Repeatability error is less than ± 1.0%; | |

Test range | Surface Area 0. 01m2 / g or more, the microporous; 0 35-2nm, mesoporous:. 2nm-50nm, macroporous: 50nm-500nm; | |

Analysis station | For precise analysis of the micro segment | |

Independent P0 | An analysis station, a station P0, two processing stations; | |

Air system | Independent saturated vapor pressure (P0) test stations, to ensure high accuracy of the partial pressure of the test; | |

Gas control valve | BEST multiple original manifold system, control valves overall integrated design, no thread seal and crimp or solder pipes interface will reduce the vacuum line to the limit, the total elimination of the leakage point, the entire system leakage rate of less than 10-10Pa * m3 / s, sealing more than 5 times, reaching the level of imports of high-end equipment, greatly enhance the stability and accuracy of the instrument; the various parts of the gas system integrated modular assembly, which greatly reduce the failure rate , greatly enhanced the stability of the instrument. | |

Diameter pipe | Using imported Japan SMC gas control valves, the complete elimination of heat generated by the solenoid valve gas thermal expansion problems. | |

Cold trap | Chase Drive is a prerequisite for high-vacuum degassing bits and test bits using large diameter valves and lines, so that the vacuum pump ultimate vacuum to be reflected maximum effect. | |

Vacuum System | Degassing gas line, gas analysis dual independent cold trap device, completely remove the gas path of the water, oily substances and other impurities; | |

Pressure Measurement | Instrument is equipped with two independent vacuum systems, both degassing system and analysis system independent of each other; the degassing system with separate two-stage mechanical vacuum pump, the ultimate vacuum reached 10-2Pa, analyze position with a separate two-stage mechanical vacuum pump imported from Germany + turbo molecular pump, the ultimate vacuum reached 10-6Pa; two independent vacuum system that is composed of three pumps to improve the efficiency of the test, and really eliminate the mutual impact analysis and degassing are carried out simultaneously between, avoid the set vacuum system brought pollution problems. | |

Pre-treatment | Imported film capacitive pressure sensor, a staging: 0-1000torr, 0-10torr, 0-0.1torr; reading accuracy error ≤0.10%, is currently the most accurate pressure sensor; micro segment partial pressure P / P0 up to 1 × 10-8, more than 50 points; large bore section having P0 real-time test function, so P / P0 control accuracy when the spirit world tends to reach 0.998 points. | |

Sample Type | 2-way degassing station has individual climate control, and an independent timing, sample degassing treatment can support and test carried out simultaneously at different temperatures and at different times; | |

Level Control | Having a "normal heating vacuum molecular diffusion mode" and "molecular replacement mode" in two optional features; sample preparation method of molecular replacement static mode molecular diffusion model efficiency by more than 1 times, can save more than half of the pretreatment time, solve the problems of problem a long time; | |

Calibration gas | Degassing treatment, a vacuum degree of 4 × 10-2Pa after two vacuum switches automatically to ensure that the sample is not drawn to fly under the premise, better residual moisture removed from the sample, and to shorten the pretreatment time, improve test efficiency. | |

Test gas | Powders, granules, fibrous sheet material and the like can be loaded sample tube material. | |

Anti-pumping fly | Liquid nitrogen to keep the original surface servo system, the elimination of the testing process because the liquid nitrogen so that nitrogen volatilization surface changes brought dead volume change, improve test accuracy. | |

Vacuum pump | With 99.9999% high purity HE; having mad HE volume test functions and test functions zone; achieve higher accuracy; | |

Liquid nitrogen Cup | High purity nitrogen according to user needs and choose a variety of gases, such as, CO2, Ar, Kr, etc., with a 4-way air intake. | |

Instrument Specifications | Original principle of vortex dust flying hardware anti-pumping device, in combination with software anti-fly program drawn eliminate volatile samples at high vacuum elutriation boiling phenomenon in order to avoid contamination of the volatiles valve piping system after causing tightness decline Happening. | |