Ultrasonic testing

- Products

- Petroleum & Oil Testing

- Tablet Drug Tester

- Refrigeration & Cryogenic

- Life Sciences

- Laboratory

- Spectrometer

- Spray Dryer

- Rotary Evaporator

- Reactor

- Sterilizing & Cleaning

- Water Quality Analyzer

- Chemical Analysis

- Physical Testing

- Centrifuge

- Pathology Equipment

- Optical

- Ultrasonic Homogenizer

- Packaging Testers

- NDT

- Agriculture & Food

- Hazardous Chemical Detection

- Fusion Machine

- Testing Chamber

- Filter Integrity Tester

- Industry Testing Device

- Featured

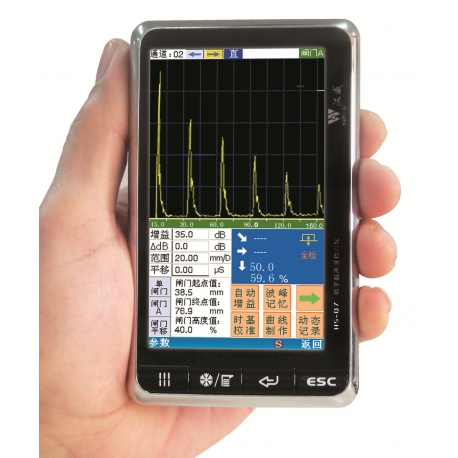

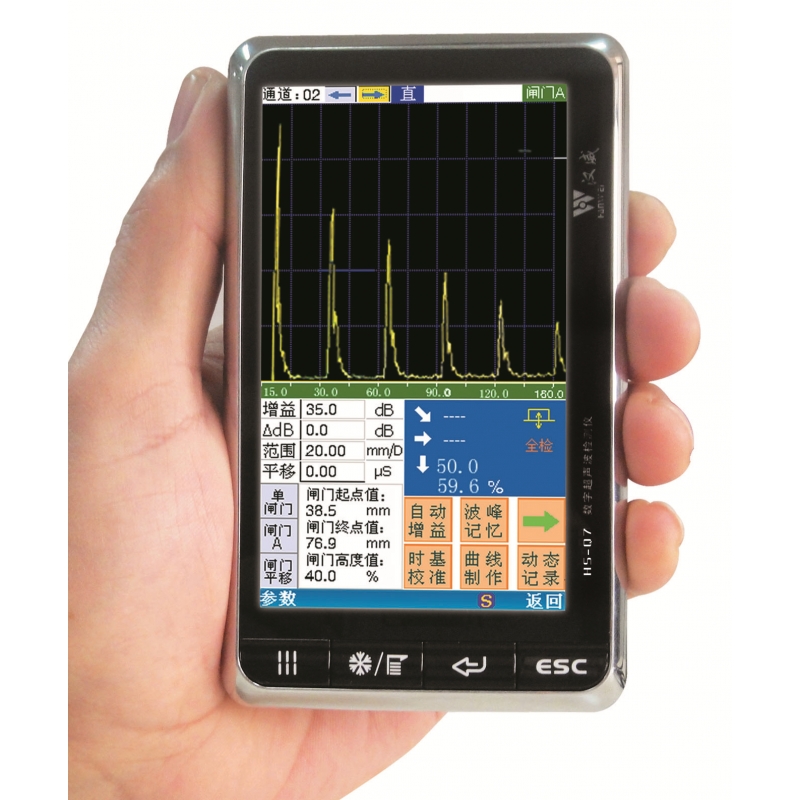

Digital Ultrasonic Flaw Detector

HS Q7

The ultrasonic flaw detector is a device that can be used for the detection of many flaws in the materials. Flaw detection is an important process that is commonly used for various purposes. The most common use of flaw detection can be seen in various engineering works. The process is commonly employed in the detection of metal surfaces.

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

More info

Features:

Very light, only 300g, like mobile phone

With touch screen and hot-key due operation models

With high-light 4.3 inch TFT screen

With high performance Li-battery, we supply 2 batteries for one instrument, to support long time working

With metal shell to protect the instrument

With high-speed USB interface

With LEMO-00 probe interface

With large storage space, can record

With large SD storage space, can record the dynamic testing waveform for more than 4 hours, can save 1000 sets testing waveform

With function to Measure the defect height with diffraction signal of defect tips

With function to display the defect location in weld saw section

Specifications | |

Excitation pulse | minus square-wave |

Pulse voltage | 300V |

Probe mode | single or dual transducer |

Testing range | 0-6000mm |

Repetition frequency | 10-1000Hz adjustable |

Sampling frequency | 100MHz/10bits |

Rectify mode | dual, plus, minus, and RF wave display |

Working frequency | 0.5MHz-15MHz |

Attenuator accuracy | < ±1dB/12dB |

Gain | 110dB (step by 0.1dB, 2dB and 6dB) |

Sound speed | (100-20000)m/s |

Dynamic range | ≥30dB |

Vertical linear error | ≤3% |

Horizontal linear error | ≤0.1% |

Surplus sensitivity | >60dB |

Digital suppression | (0-80)% |

Working time | more than 4 hours (supply by Li-battery) |

Working temperature | -10-40 ℃ |

Working humidity level | (20-95)% RH |

Size | 128 * 76 * 22 (mm) |